Stainless steel is an excellent material not only for its corrosion resistance but also for its heat resistance, workability, strength, and appearance.We enhance the quality of stainless steel through various surface treatments while taking advantage of its characteristics.

For our full product, please contact us

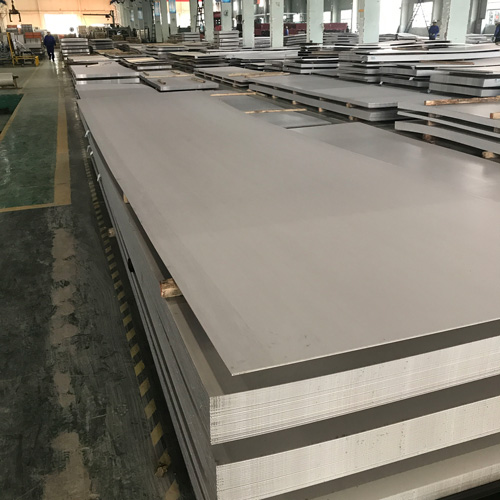

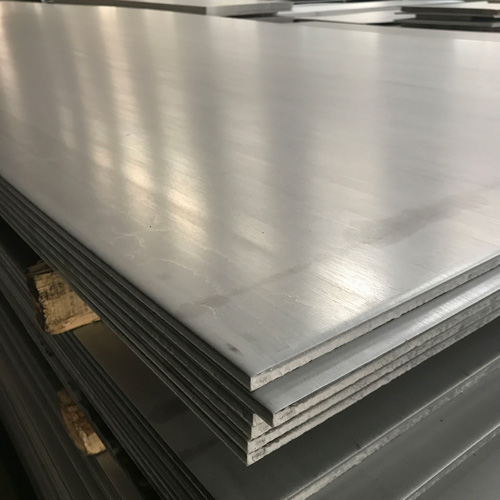

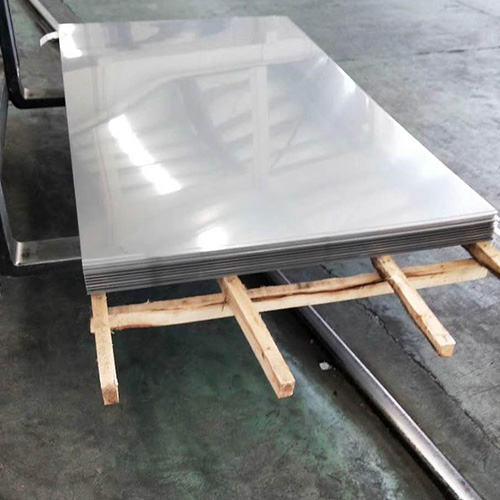

Inquiry Price >The No. 1 surface is the original surface of the steel sheet obtained after hot rolling, heat treatment and pickling. The surface is rough and matt.

Processing type: hot rolling, annealing, descaling

Condition features: silvery white, matt,rough surface

Processing technology: After hot rolling to the specified thickness, it is then annealed to remove phosphorus and scale to obtain a matte surface.

Usually used in industrial use, the thickness is thicker, from 2.0MM-8.0MM. Heat and corrosion resistant, generally used in applications where surface smoothness is not critical.

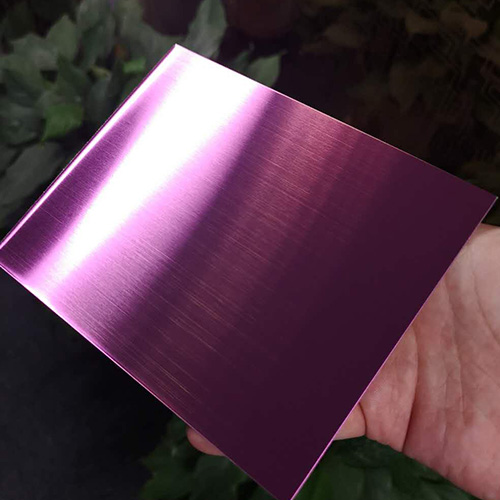

Stainless steel NO.4 surface is a stainless steel wire drawing process. The drawing process is to use water or metal emulsion for surface drawing processing, compared with dry drawing, stainless steel oil grinding drawing surface more metallic luster. In general, there is no fingerprint drawing refers to the oil grinding wire drawing, because its surface has a layer of oil grinding cover, whether it is fingerprint resistance, corrosion resistance than dry drawing will be better. The surface of the stainless steel oil grinding wire has a layer of inorganic material film combined with the steel plate as a molecular form of the body, which has certain fingerprint resistance and corrosion resistance. Stainless steel NO.4 surface is a stainless steel wire drawing process. The drawing process is to use water or metal emulsion for surface drawing processing, compared with dry drawing, stainless steel oil grinding drawing surface more metallic luster. In general, there is no fingerprint drawing refers to the oil grinding wire drawing, because its surface has a layer of oil grinding cover, whether it is fingerprint resistance, corrosion resistance than dry drawing will be better. The surface of the stainless steel oil grinding wire has a layer of inorganic material film combined with the steel plate as a molecular form of the body, which has certain fingerprint resistance and corrosion resistance. It can grind stainless steel coils with thickness of 0.4mm-3.0mm and width of 550mm-1500mm. It can grind 200 series, 300 series and 400 series stainless steel cold rolled coils with double sides, and the maximum grinding speed can reach 35m/min. Add a certain amount of metal emulsion to the surface of silk drawing processing, making the surface more glossy. This drawing method, do not add anything, without water surface drawing, plate surface with oil grinding water grinding in the finish and smoothness are obvious differences.

Hairline surface is a hairline-like surface obtained after the stainless steel surface is brushed, straight-drawn and matte.

Stainless steel wire drawing board is actually the texture obtained after the surface treatment of stainless steel, which is a processing technology of stainless steel. Its surface has a matte color. If you look closely, there is a trace of texture on the surface, but you can't feel it with your hands. It is more wear-resistant than ordinary bright stainless steel, and it looks more high-grade, and the processing technology is relatively simple. After processing, many straight lines are formed on the surface. This process will not only reflect the beauty, but also eliminate some scratches on the surface of the stainless steel plate, which is very practical.

Features: HAIR LINE hair-like continuous silk pattern, luster similar to No.4 Hairline grinding, using the appropriate particle size abrasive material for hairline grinding (150-240#) to form continuous stripes, it is often used in building decorations such as elevators, escalators, etc., and has a wide range of uses.

Application in the construction industry: elevator door panels, escalator decorative panels, cabinets such as range hoods, stainless steel stoves, sinks, etc.

Now it is also widely used in various 3C digital products, such as notebook computer panels, keyboard panels, LCD frames, battery covers, etc.

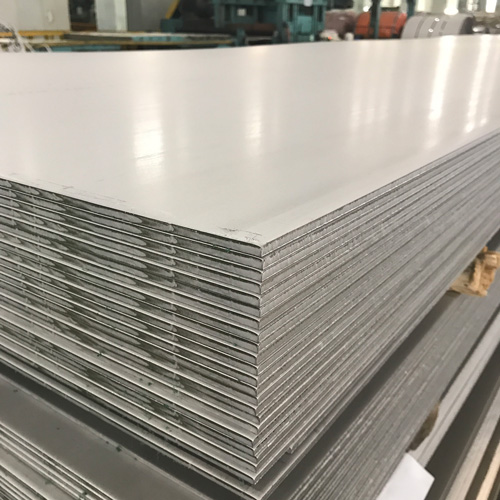

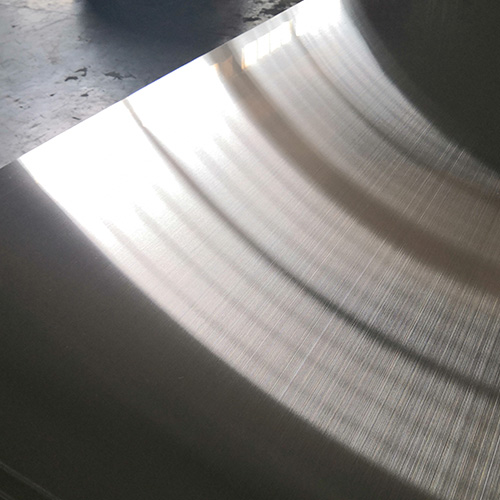

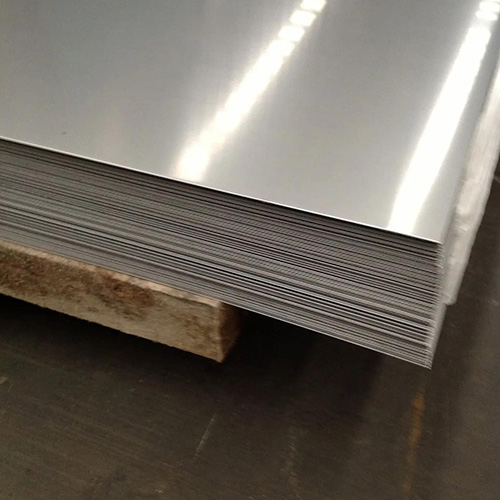

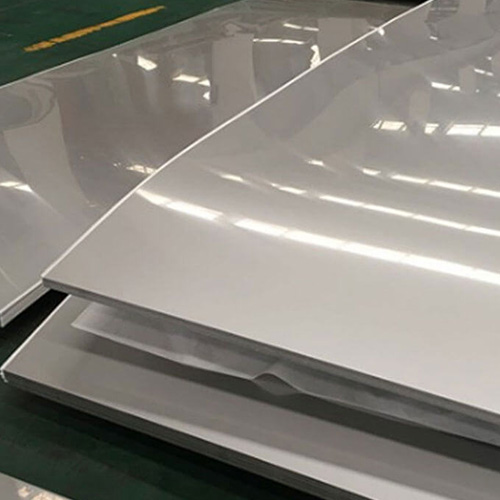

2B surface is cold rolled after heat treatment, pickling, and then finish rolling processing to make the surface of moderately bright steel pipe surface. Because the surface is smooth, easy to regrind, make the surface more bright.

Stainless steel tube 2B surface gloss and smoothness is stronger than 2D surface, 2D surface treatment, after polishing roller for the final light cold rolling, in order to obtain appropriate gloss. This is the most commonly used surface finish, which can also be used as the first step in polishing.

2B surface is more widely used, such as tableware, building materials, etc. After using the surface treatment to improve mechanical properties, almost all products can be used. Compared with the common 2B surface, the 2D surface is less smooth than 2B surface, but the overall surface is still very uniform, a matte. 2B is superior from smooth degree, burnish./p>

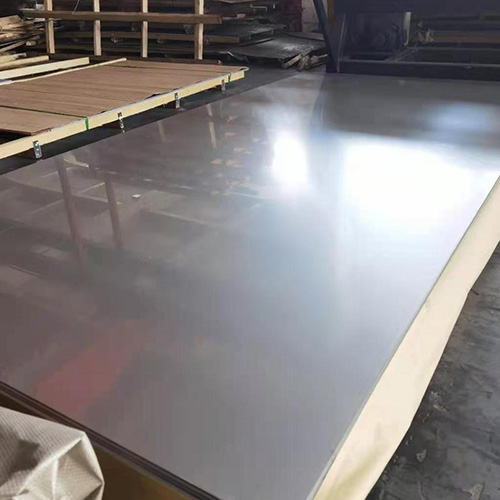

Grade 304 Stainless Steel sheet is a popular and versatile cold rolled product that is available in a choice of surface finishes. On this page, we will be looking at Grade 304, Bright Annealed Stainless Steel Sheet otherwise known as BA.

Bright Annealing is a heat treatment during which the oxygen is removed from the atmosphere, either by creating a vacuum, alternatively by displacement as a result of the addition of dry hydrogen or argon.

The result is a fantastic decorative bright, shiny, reflective, mirror like finish on both sides of the sheet. If required, this can then be buffed to produce an even better and more reflective finish.

Grade 304 bright stainless steel sheet is suitable for bending – should you require your stainless steel sheet folding then please contact us for a quote.

Although the Bright Annealed finish is not quite as perfect and reflective as mirror polished stainless steel sheet, it is very close and is an excellent cost effective alternative. Another advantage of Bright Annealed Stainless Steel sheet against Mirror Polished Stainless Steel is that as with any kind of polish, a mirror polish will be removed when scratched – but because Bright Annealing is a heat treatment, the material is shiny all of the way through the thickness of the sheet and therefore will still remain bright if scratched.

All of our Bright Annealed Stainless Sheet comes with a protective PVC coating on one side of the sheet to help protect is smooth, bright & shiny finish during the cutting process. Once your sheet has been delivered and your project is complete, simply peel off the PVC coating, and you will be left with a blemish free shiny surface.

Mirror glossy, bright annealed. This finish is also produced by cold rolling and de-scaling but in this case the final annealing is done in a controlled atmosphere furnace. The effect of annealing without the presence of oxygen is to produce a reflective surface on the stainless steel and it is often used in preference to a 2B finish where reflectivity is important, such as catering equipment. The very smooth surface also makes this surface highly suitable for further finishing processes such as mirror polishing and chrome plating.

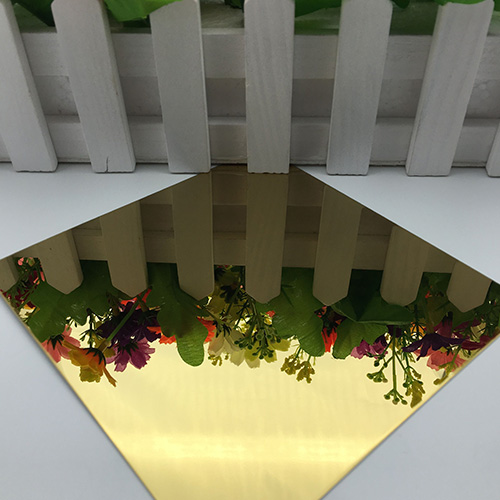

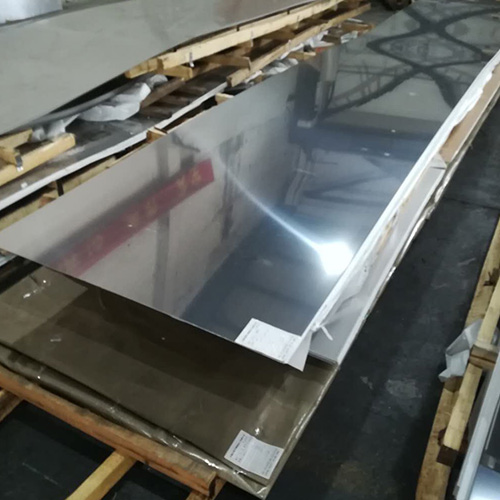

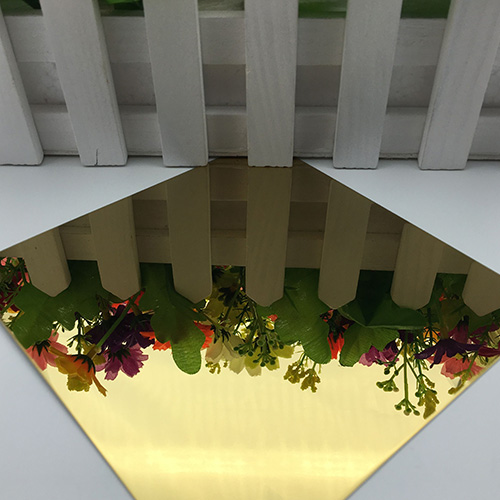

Common mirror stainless steels are divided into three types: 6K, 8K, and 10K. Generally, it is ordinary polishing, ordinary 6K, fine grinding 8K, and super fine grinding 10K effect. The same thickness is generally not much difference, the 10K mirror is brighter; the thicker the thickness, the worse the effect and the higher the processing cost

Mirror stainless steel is widely used, such as elevator panels, building materials panels, etc. It is also commonly used in interior product decoration! For example, the mirror wall in the guest room can expand the space and enhance the overall three-dimensional feeling! It can also be used as a TV wall, with a stainless steel decorative mirror, which doubles the sense of luxury!

Colored stainless steel was invented in the 1970s and is used in building materials, chemicals, automobiles and other fields.

The color stainless steel plate not only maintains the physical, chemical and mechanical properties of the primary color stainless steel, but also has stronger corrosion resistance than the primary color stainless steel.

The current color stainless steel plate is gorgeous in color and is a very good decorative material. It is used for decoration to show the quality of glory and luxury. The color will change with the light angle. The color stainless steel plate and the color surface layer can withstand the temperature of 200 ℃, and the salt spray corrosion resistance is better than that of ordinary stainless steel. The wear resistance and scratch resistance of the colored stainless steel plate is equivalent to that of foil coating. Gold properties. When the color stainless steel plate is bent at 90 °C, the color layer will not be damaged, and it can be used for decoration of hall wall panels, ceilings, elevator car panels, car box panels, building decoration, signboards, etc. Color stainless steel panels are generally used to decorate walls .